Therefore, selecting the appropriate ventilation equipment is a crucial task for HVAC professionals. Wrong decisions can result in serious consequences.

Examples include:

- Insufficient capacity

A poorly selected air handling system may have insufficient air processing capacity. As a result, the supplied air may not meet certain specifications, which is unlawful and affects occupant safety and comfort. The equipment must have sufficient power and capacity to provide fresh air to every room in the building. - Non-optimal performance

If the ventilation system is not properly designed and optimised, it may generate excessive operating costs. A well-selected air handling unit (AHU) ensures lower energy costs.During the initial engineering phase, project owners often request their units to be as powerful as possible. However, this can result in significantly higher operating costs, particularly in terms of electricity or gas consumption. Environmental concerns and rising fuel prices make optimisation of AHUs crucial.

But optimising the results is more than selecting the appropriate power. It also involves selecting the most suitable equipment, accessories, and components, as well as the layout of air ducts (with special attention to their length and pressure distribution) and the AHUs themselves.

- No planning for the future

Failure to plan for future demand can also prove very expensive. If at the stage of planning a ventilation system it is known that the demand for ventilation will increase in the future (e.g. the building will be redeveloped or expanded, the purpose of the building will change, the number of employees and customers will increase, etc.), this should be included in the design. Careful planning, with the future in mind, will likely translate into a significant reduction of costs associated with any subsequent modification or expansion of the ventilation system.HVAC Ratherm specialists can help you plan your air handling system with consideration for future needs. We help our customers reduce costs and save time. If you want to learn more, please do not hesitate to contact us.

- Too much noise

Excessive noise from incorrectly selected and poorly designed air handling system can be disruptive to occupants. Although every mechanical ventilation device produces sounds while in operation, a well-selected AHU installed in the right location will be practically inaudible.However, in extreme cases, noise may arise within the HVAC system itself due to excessive air speed. This type of noise may also be very burdensome to occupants. To avoid such issues, it is crucial to select and design AHUs properly. This will ensure the correct air noise level both in the air ducts and outside the enclosure.

There are many other sources of noise made by an AHU. They include vibrations, worn bearings or mechanical damage. HVAC Ratherm has its own dedicated AHU servicing team,and our experts are always happy to help.

- Insufficient heat recovery

One of the most efficient ways to reduce the operating costs of a HVAC system is the use of heat recovery.In a traditional mechanical ventilation system without heat recovery, the stale air is simply expelled from the building, but this air was likely heated earlier. In addition, heating is one of the highest operating costs for a building, so utilising this energy instead of removing it makes a lot of sense.

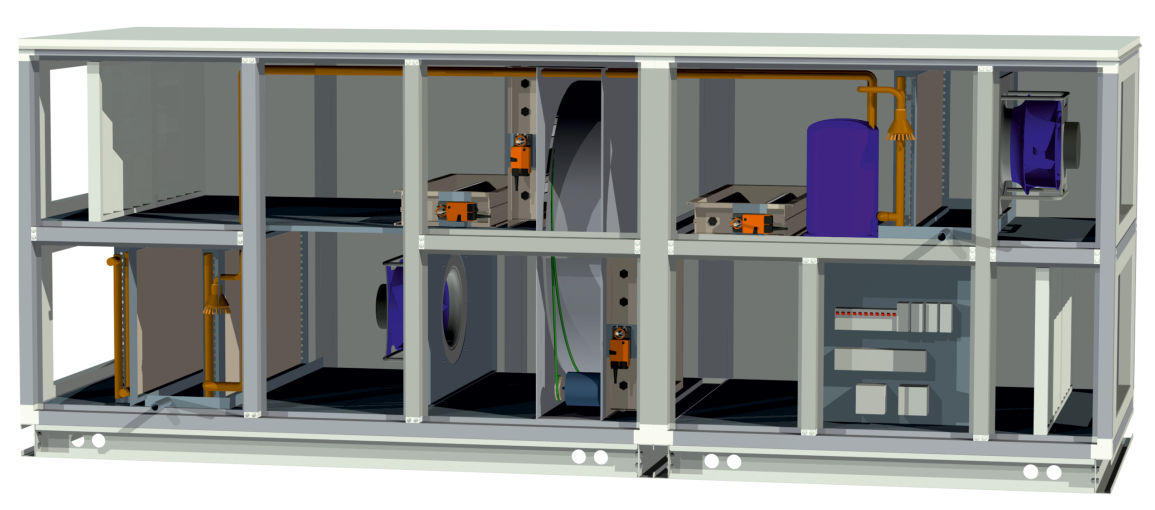

Therefore, HVAC Ratherm offers AHUs equipped with a heat recovery module, such as our monoblock XD AHUs. These modules use the heat from the aged air to warm the fresh air being supplied to the building, reducing overall heating demand and expenses. Heat recovery does not replace heating entirely, but it does make a significant impact on cost reduction.

Therefore, not using equipment with a heat recovery capability where it would be suitable to do so is yet another example of poor decision-making. This is an entirely needless loss of energy.

Heat recovery also has a positive impact on the environment by decreasing energy consumption and air pollution from fossil fuel combustion.

Monoblock AHUs and gas-fired AHUs or compact AHUs manufactured by HVAC Ratherm may be installed on rooftops. This frees up valuable space that would otherwise be taken up by the unit. In addition, we have managed to significantly reduce audible noise. Our AHU designs incorporate solutions to further minimize noise produced by the working unit.

mon-fri: 08.00 - 16.00

mon-fri: 08.00 - 16.00 ul. Agrestowa 3, 83-010 Rekcin

ul. Agrestowa 3, 83-010 Rekcin