Air Handling Units Effective air circulation

Why our units?

The technology inside

Nowadays air handling units are essential for ensuring proper thermal comfort and air purity in most buildings. A key aspect of achieving the desired effect is matching the type of device to the purpose of the building.

HVAC Ratherm's offering includes most types of air handling units, which guarantees the best device-facility synergy. HVAC Ratherm offers standing, horizontal, and suspended units, in outdoor and indoor execution. This includes compact and sectional units. The devices can be equipped with various types of heat recovery, as well as different types of heat and cooling sources, such as gas heaters, electric heaters, or wather cooling and heating coils. Air-to-air type heat pumps and condensing units are also used in HVAC Ratherm AHUs. These devices ensure we can provide our customers with reasonalbly priced heating and cooling.

In its designs and products, HVAC Ratherm strives to minimize investment and operating costs by applying, among others, the latest solutions in terms of components used and structural designs. High-efficiency EC fans and heat recovery systems, inverter compressors, and proprietary technologies and solutions, such as MagicBox or R-Box, form the basis of the effectiveness and reliability of Ratherm air handling units.

However, Ratherm's activity is not limited only to air handling units, but also includes accompanying products, such as multi-blade dampers or a roof support system, which significantly facilitate the daily work of installation and contracting companies.

Ratherm air handlig units- Overview of units and mounting systems

Supply and Exhaust Air Handling Units

The fundamental solution for most facilities. It provides controlled supply and exhaust airflow, the possibility of zone balancing, and stable integration with energy recovery systems and automation. Used in office, commercial, and service buildings, as well as in industrial technological applications.

Rooftop Units

Used when saving internal floor space and simplifying ductwork installation is a priority. Roof-mounted installation shortens duct routes, facilitates engine room organization, and often simplifies service access—provided that maintenance and positioning are properly planned.

Suspended Units

A solution designed for ceiling voids and facilities without a dedicated engine room. Key factors include installation height, connection layout, access to filters and heat exchangers, and fan servicing. They perform exceptionally well where every square meter of floor space is at a premium.

Compact Ventilation Units

Selected when reduced dimensions and rapid implementation in a standard functional layout are required. The compact design facilitates transport and assembly, while proper selection ensures full functionality typical of heat recovery installations.

Frameless Air Handling Units

Used in systems where a simplified form and a reduced number of structural supporting elements are preferred, while maintaining required airtightness and insulation. In practice, service ergonomics, casing rigidity, and refined connection solutions are the most important factors.

Ductless Air Handling Units

A solution for facilities where an extensive duct network is a constraint (due to collisions, height limits, costs, or assembly logistics). The ductless system limits the scope of installation work but requires a conscious design of zones and air distribution methods within the hall.

Monoblock Units

One casing, one control system, one set of connections—in practice, this means easier assembly and service coordination. Monoblock units are selected where consistency of the air treatment system and a reduction in the number of separate devices are essential.

Gas-Fired Units

Used when gas is the primary energy source for air heating, justified by the facility's energy balance. In such systems, key priorities include safety, compliance with installation requirements, proper automation selection, and predictable operation in varying outdoor conditions.

Multi-leaf Dampers

In flow regulation and shut-off systems, repeatability of settings and airtightness are crucial. Multi-leaf dampers are used in rectangular ducts and unit sections for balancing, mixing, or shut-off functions, and are designed to work with automation actuators.

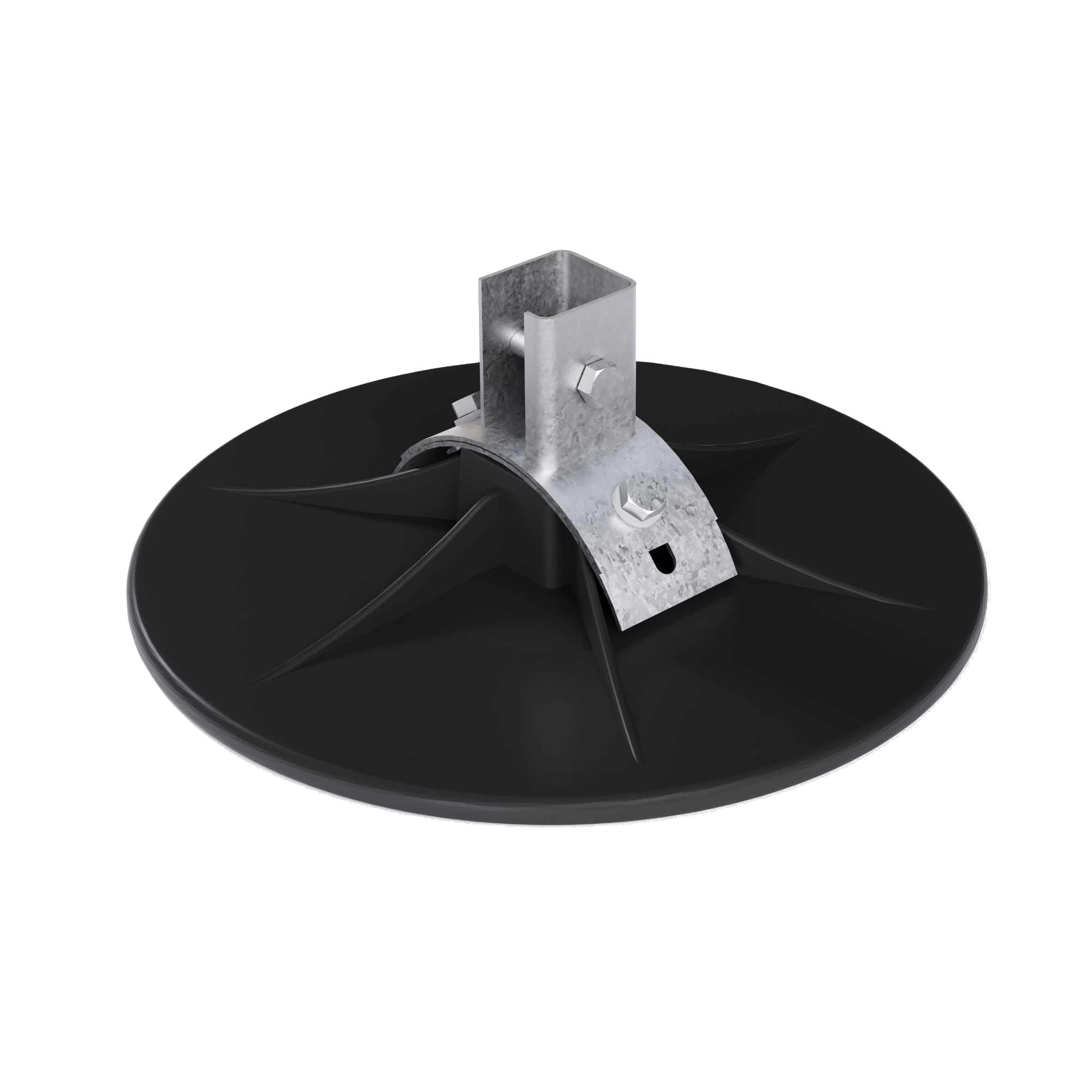

Roof Supports

Proper positioning of the unit on the roof reduces the risk of assembly and operational issues. Roof supports are selected based on the unit's weight, load distribution, and roof geometry. The result: stable unit operation, organized installation, and reduced vibration transmission to the building structure.

Benefits of purchasing a HVAC Ratherm unit

|

| Technical consulting and custom quote |

|

| Support with accessory selection (sensors, filters, ducts) |

|

| Spare partsavaliability |

|

| Service and warranty door-to-door |

Reducing investment costs

In its designs and products, HVAC Ratherm strives to minimise both investment and operating costs by applying the latest solutions in terms of used components and structural design. High-efficiency EC fans and heat recovery systems, inverter compressors, as well as proprietary technologies and solutions like MagicBox or R-Box, form the basis of the effectiveness and reliability of HVAC Ratherm air handling units.

The durability of the unit depends on the engineering details. Frame rigidity, casing air tightness class, and insulation quality determine the acoustic and thermal performance. At Ratherm, we only use components that are proven to be reliable.

Comprehensive investment support

Equipment is only part of the solution. Industrial ventilation requires a process-oriented approach, which is why RATHERM offers comprehensive support at every stage of the project:

- Ventilation Design – unit selection based on reliable calculations of air demand, static pressure, and thermal balance.

- AHU Installation – professional assembly, positioning, and automation system integration.

- AHU Service & Maintenance – warranty and post-warranty technical care, including regular inspections and filter replacements.

FAQ